In the world of modern electrical engineering, conductor stranding is far more than a structural detail—it’s a critical factor that directly influences a cable’s performance, flexibility, and longevity. Whether you’re designing high-frequency data cables, industrial power lines, or aerospace wiring systems, understanding how conductors are stranded can determine the overall success of your electrical application.

At its core, conductor stranding refers to the process of twisting multiple strands of wire together to form a single, flexible conductor. This manufacturing technique not only improves the mechanical properties of the wire but also enhances electrical characteristics like resistance to vibration, reduced skin effect, and improved current distribution.

This blog post aims to be your comprehensive guide to mastering conductor stranding. We’ll explore different stranding types (bunch, concentric, rope), classify various stranding standards (Class A through M), and explain how these affect flexibility, durability, and conductivity. Drawing on industry insights, global standards (UL, ASTM, IEC), and real-world use cases, this guide is tailored to electrical engineers, cable designers, and technical decision-makers seeking data-backed knowledge to optimize their cable selection and design processes.

If you’ve ever wondered why one stranded wire behaves differently than another—or how conductor stranding impacts cable performance under stress, heat, or movement—this article will provide the clarity you need. Let’s dive into the intricate science behind conductor stranding and understand why it matters more today than ever before.

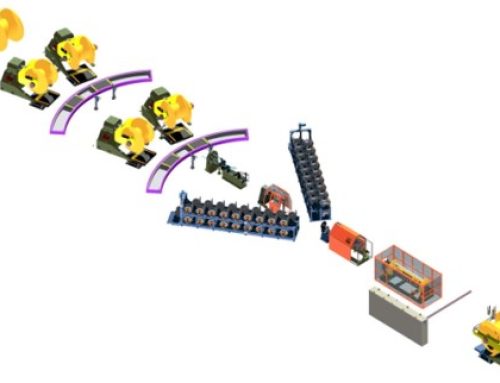

drum twister hattı assembling and armouring line

This article may interest you. How Cable Stranding Machines Enhance Product Quality

What Is Conductor Stranding?

Conductor stranding is the process of twisting multiple small wire strands together to form a single conductor. Unlike solid conductors—which consist of a single piece of metal—stranded conductors offer improved flexibility, vibration resistance, and durability in dynamic environments.

There are various methods used in stranding, but the goal remains the same: to create a conductor that can handle mechanical stress without breaking, especially in applications where the cable needs to move or bend frequently.

Stranding also influences electrical performance. For example, stranded conductors have a slightly higher resistance than solid ones of the same size, but they reduce issues like skin effect in AC applications by allowing better current distribution across strands.

This technique is commonly used in power cables, control wires, automotive wiring, and robotics—basically, anywhere that flexibility and mechanical endurance are needed.

Why Stranding Matters in Electrical Applications

Stranding isn’t just a manufacturing detail—it’s a performance driver. In electrical applications, the way a conductor is stranded affects both mechanical behavior and electrical efficiency.

Stranded conductors offer superior flexibility, making them ideal for installations where movement, bending, or vibration is frequent—such as in automotive, robotics, or portable electronics. A solid conductor may break under repeated motion, while a well-stranded wire maintains integrity and continuity.

Mechanically, stranded wires also have better fatigue resistance and are less prone to cracking under stress. Electrically, they help mitigate issues like the skin effect, where high-frequency AC current tends to travel near the surface of a conductor, potentially limiting performance. The multiple strands increase surface area, improving current distribution in such scenarios.

In short, choosing the right stranding technique ensures that a cable not only performs efficiently but also lasts longer in demanding conditions.

Types of Stranding Techniques

There are several stranding methods used in cable manufacturing, each designed to meet different mechanical and electrical needs. Here are the three most common techniques:

1. Bunch Stranding

This method twists wires together without any specific arrangement. It’s simple, cost-effective, and offers good flexibility. However, it doesn’t provide uniform spacing between strands, which can slightly reduce electrical performance in precision applications.

2. Concentric Stranding

In this method, strands are layered evenly around a central wire, each layer twisted in the opposite direction. This structure provides better mechanical balance and consistent electrical behavior. It’s widely used in power distribution and control systems.

3. Rope Stranding

Rope stranding takes several concentric or bunched groups and twists them together, forming a rope-like structure. It offers maximum flexibility and is ideal for high-motion environments like robotics or drag chains.

Each technique involves a trade-off between cost, flexibility, and performance. Selecting the right one depends on the application’s specific mechanical stress, frequency, and installation conditions.

Stranding Classes and Standards

Conductor stranding is categorized into standardized classes that define the level of flexibility and strand arrangement. These classes are essential when selecting a conductor for a specific environment or mechanical requirement.

Class A & B

These are standard classes for power and control cables.

- Class A is typically used for solid or semi-solid conductors in fixed installations.

- Class B is the most common stranded configuration, offering a good balance between strength and limited flexibility.

Class C & D

- Class C provides more flexibility than B, ideal for applications with occasional movement.

- Class D is more flexible still, often used in control panels and light-duty industrial use.

Class G, H, I, K, M

These are high-flexibility classes:

- Class G & H are used in portable equipment and cords.

- Class K and M are designed for very high flexing cycles, such as robotics and automation systems.

These classifications are defined by standards such as UL, ASTM, and IEC, helping manufacturers and engineers ensure consistent performance across different cable types.

Choosing the right class ensures the cable withstands mechanical stress while maintaining electrical performance.

How Stranding Affects Electrical Performance

The way a conductor is stranded directly impacts how electricity flows through it. While stranded conductors are primarily chosen for their mechanical flexibility, they also affect electrical behavior in key ways.

1. Resistance and Conductivity

Stranded wires have slightly higher electrical resistance than solid wires of the same gauge. This is due to small air gaps between strands and the greater surface area of each strand. However, in most low-voltage or flexible applications, this increase is negligible.

2. Skin Effect in AC Circuits

At higher frequencies, alternating current tends to travel near the surface of a conductor—a phenomenon called the skin effect. Stranded wires, by nature, have more surface area, which can help distribute current more evenly and reduce losses in AC applications.

3. Heat Dissipation

Because of their structure, stranded conductors may dissipate heat more efficiently in some cases, especially when compacted or compressed stranding methods are used. This can contribute to cable longevity under continuous load.

In summary, while solid conductors may offer slightly better conductivity, stranded conductors provide a better balance between electrical performance and mechanical flexibility, making them more suitable for dynamic or high-frequency environments.

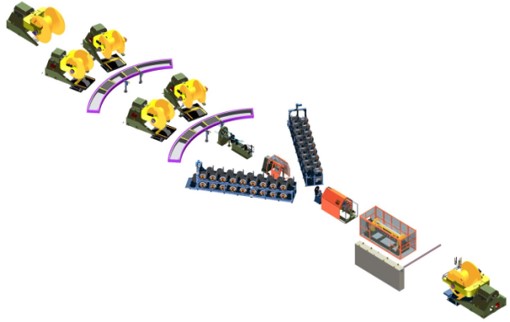

yerden gezer toplayici verici floor type pay off take-up

This article may interest you. A Complete Guide to Conductor Stranding Techniques

Choosing the Right Conductor Stranding

Selecting the right stranding type is not just a matter of cost—it’s a strategic decision based on the mechanical demands, installation conditions, and electrical requirements of your application.

🔧 Flexibility Needs

If the cable will be bent frequently or used in a moving environment (e.g., robotics, vehicles, drag chains), high-flexibility classes like Class K or M should be prioritized. These cables resist metal fatigue and maintain integrity under constant motion.

🧱 Fixed Installations

For stationary applications such as building wiring or switchboards, Class B or C stranding is usually sufficient. These provide adequate flexibility for installation while maintaining solid electrical performance.

⚡ Electrical Load and Frequency

In high-frequency AC systems, stranded conductors help reduce skin effect losses. If the application involves signal transmission or high-speed data, finer stranding or specialized configurations may enhance performance.

💡 Installation Conditions

Consider space constraints, bending radius, and environmental factors. Tightly packed systems may benefit from compacted stranded conductors, which reduce overall cable diameter without compromising performance.

To sum up, there’s no one-size-fits-all approach. The ideal stranding depends on balancing flexibility, durability, conductivity, and installation environment—each factor matters.

Common Mistakes to Avoid

Even experienced professionals can make critical errors when selecting or applying conductor stranding. Here are the most common pitfalls—and how to avoid them:

❌ Using the Wrong Stranding Class

Choosing a lower flexibility class for a high-movement application can lead to early conductor fatigue and failure. Always match the stranding class to the mechanical requirements of your system.

❌ Ignoring Bending Radius

Over-bending stranded cables can cause internal strand breakage, reducing performance and lifespan. Always follow manufacturer-recommended minimum bend radii, especially for high-flex cables.

❌ Overlooking Compact Stranding Benefits

In dense control panels or space-limited installations, not using compact stranding can result in bulky cables that are harder to manage. A more compact strand structure can save space and improve thermal dissipation.

❌ Assuming All Stranded Conductors Are the Same

Not all stranding types behave the same. Bunch, concentric, and rope stranding each have unique properties. Selecting the wrong type can lead to unintended electrical or mechanical issues.

Avoiding these mistakes can help ensure your cable performs reliably, lasts longer, and complies with safety and performance standards.

Future Trends in Conductor Stranding

As technology advances, so does the need for smarter, more efficient, and more adaptable conductor designs. Here are some key trends shaping the future of conductor stranding:

🔄 Automation in Stranding Processes

Modern stranding machines are increasingly integrated with automation and AI-based controls, enabling precise tension control, faster production speeds, and better consistency. This minimizes human error and enhances cable quality.

🌱 Sustainable Manufacturing

There’s growing demand for eco-friendly cable production, including the use of recycled copper, energy-efficient machines, and waste reduction in stranding processes. Green certifications are becoming a key differentiator.

⚙️ Advanced Materials and Micro-Stranding

The use of nano-alloy wires and ultra-fine micro-stranding techniques allows for lighter, more conductive, and more flexible cables—especially valuable in aerospace, medical devices, and electric vehicles.

🧠 Smart Cable Integration

As IoT systems expand, conductors may soon include embedded sensors or conductive polymers that allow real-time monitoring of cable health, temperature, or load.

These trends reflect the industry’s push toward higher performance, longer life cycles, and smarter systems—making conductor stranding a continually evolving field.

kılıf hattı sheathing line

Conclusion

Conductor stranding is more than a technical detail—it’s a foundation for cable performance, reliability, and application success. Whether you’re building power systems, industrial automation lines, or high-frequency communication networks, the right stranding method determines not only how well your cable performs, but how long it lasts.

Understanding different stranding types, classes, and electrical impacts allows engineers and decision-makers to optimize both design and budget. As technology evolves, staying informed about new materials, smarter manufacturing, and sustainability will be essential.

In short, mastering conductor stranding means building better, safer, and more efficient systems.