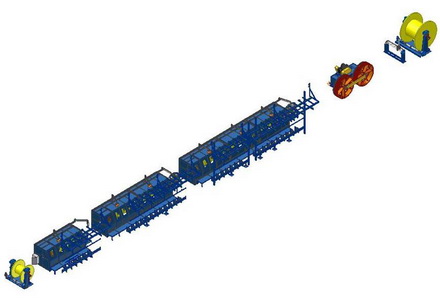

Central Strander Machine Bakır 07 Line

High production rate – Low energy consumption – Wide production range – Safe production

Central Strander Machine Bakır 07 Line

It is a central wire twisting machine with international patent (Patent: 2008/06114), high speed and efficient, copper/aluminum wire twisting and control cable twisting within the scope of TÜBİTAK-TEYDEP project. Copper 07 machine produces up to 61 wires in round (compact/non-compact) or sector form.

Copper 07 (1+6+12+18), up to 37 wires, 240mm2 in single stage, 300-400-500mm2 in double stage; Copper 07 (1+6+12+18+24) has the capacity to produce up to 61 wires 500 mm2 in one step and 630-800-1000 mm2 in two stages.

It is one of the advantages of being a machine that is up to 2 times more efficient, high energy saving and faster than other twisting machines.

In addition, optionally, aluminum wire and control cable can be twisted.

Working principle, Production is in 2 stages. In the first stage, the wires are transferred from the baskets to the reels in the machine cages as needed. In the second stage, the wires are twisted.

The cages are cast steel and have a solid design. Each cage unit is driven by AC Servo motor. The cage brake is designed as a large diameter pneumatic disc brake. There is a dual circuit braking system. Normal braking time is 30 seconds, emergency braking time is 5 seconds.

Reel brakes are easily replaceable pad brakes.

Control system, all functions of the machine are done via PLC and there is also the option of monitoring over the internet.

- Wire diameter : 0.90 – 1.60 mm

- Revolution speed,max : 500 min-1

- Line speed : 70 m/min

- Power consumption : 15-20 kW